The following requirements are imposed to beet choppers: high capacity, high quality of beet chips, ease and accessibility of maintenance and repair, reliable and cost-effective operation.

Centrifugal beet chopper swith12, 16, 24 frames, with capacity of 1,5, 2 and 3 thousand tons per day.

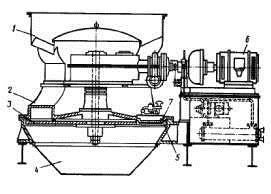

Centrifugal beet chopper СЦБ-16М (fig.) consists of cylindrical body 2, three-arm volute 3, bevel gear speed reducer, driver 8, top 5 and bottom 4 housings, feeding box 1, knife frames6, hoisting unit 7 andfinger-type hydraulicslide damper. Beetchopper is operated as follows. Beet loading into beet chopper is performed through feeding box.

Inbeetchopperbodybeetiscarriedawaybyrotatedvoluteandis centrifugally retained against cutting edge of knifes, sliding through which it gradually turns into chips.

Beetchipsthroughopeningsof knife framesfall into space between beet chopper body and housing and then through opening in bottom casing enter for the following processing.

Knifeframeswithsetofknifesare installed in holders of beet chopper body tightly, no wobbling. For frames to form inner surface of one radiustogether with beet chopper body, they are machined with body after installation. Beetchopperbodyhas patches which enable to machine it several times. Operatingandstand-byframestogetherwithbeetchopperbodyare generally machined once a sugar refining season.

Inordertoreplaceknifesinoperatingstate, beetchopperisequippedwithаrake mechanism, which lifts knife frame out of its holder,аnd it is then replaced with dead frame, which differs from operating one by absence of openings for knifes installation.

During fibrillar beet processing diffusion knifes are often blocked with fibers, that is why in order to obtain high quality chips they are cleaned by means of steam purging or air blasting with over pressure 0.7МPа. Steam and air shall be supplied to knifes so that they can blow fibers off the knives, but not forcing them against cutting edge.

In sugar industry beet slicing knives, milled from carbon and instrument steels (ridge slicing knives and konigsfeld knives) and Gollerknives, forged fromhigh-carbon steelsheet.

Standard provides manufacturing of two types of knives: no-rib knives (type 1) and rib knives (type 2) in three designs: A – left, B – right, O – non-specific. Type 1 knives have pitch 6, 7, 8, 9, 10, 12 mm, type 2 knives – 5 and 6 mm.

Ridge slicing knives manufactured for centrifugal and disk beet choppers are the most widely used at national sugar mills.

Knivesare fixed inframes,designof which dependson beet chopper typeand design ofknives: there are knifeframesfor centrifugalbeet choppers and framesfor diskbeet choppers.

Capacity, t/day:

by grooved chips.2100

by flat chips. 1500

Numberofknife frames………..16

Cutting speed, m/с……6.0…9.5

Voluterotationalspeed, с-1 . . 7.1… 11.4

Body diameter, mm……1600

Electric motor power, kW .100

Overall dimensions, mm……… 5650x2440x3000

Weight,kg……….11400